Move It. Use It. Trust It: 7 Must-Have Features of a Portable Biodecontamination System

When it comes to contamination control, the best solution is the one your team actually uses—consistently and correctly. That’s why selecting the right portable biodecontamination system is more than just a purchasing decision; it’s a strategic investment in safety, compliance, and operational efficiency.

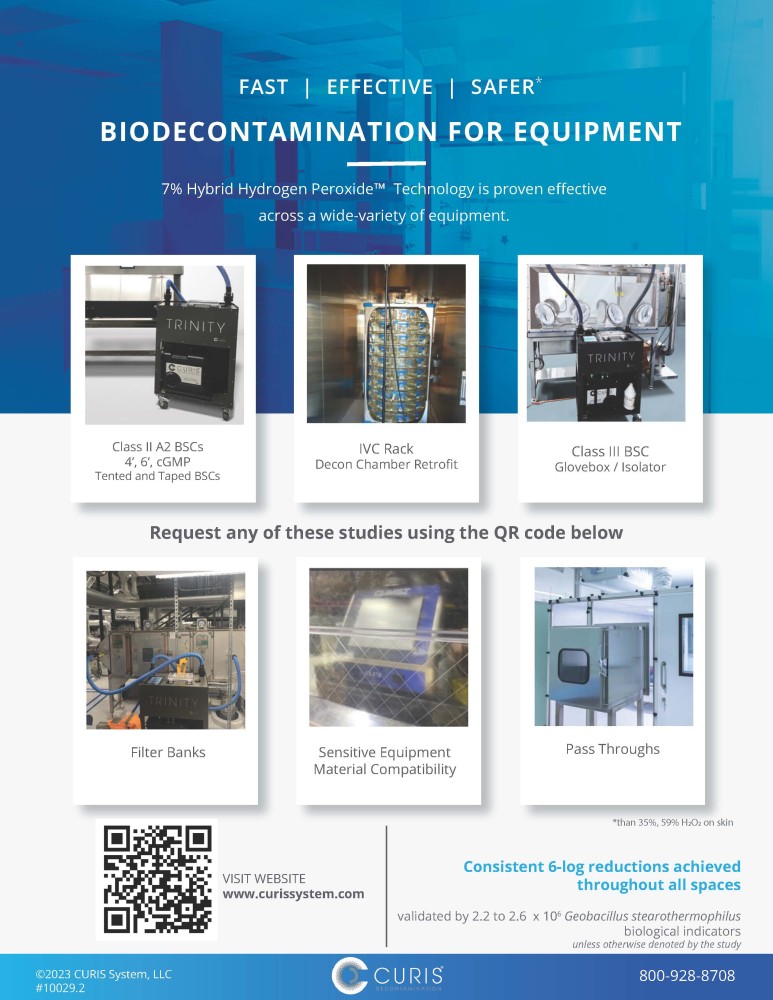

Whether you're managing a high containment lab, pharmaceutical cleanroom, or multi-site research facility, the features of your disinfection equipment can make or break your contamination control strategy. Here’s what to look for in a system designed for real-world demands—and how the CURIS 3 portable generator delivers.

-

Portability that Encourages Use

Many facilities start with high ambitions for routine decontamination, only to find their 150-lb. disinfection unit impractical to move between buildings. One multi-building site reported that their bulky unit often stayed parked in storage because moving it between labs required too much effort.

After switching to the CURIS 3—just 36 lbs. with a rolling cart—they saw immediate benefits: teams could easily roll it down hallways or lift it into a vehicle. Suddenly, regular decontamination became part of the culture. One device, multiple locations, no excuses.

“CURIS made it possible to maintain contamination control without needing multiple units or extra staff.” — Facility Manager, Pharma Manufacturing

-

User-Friendly Operation and Fast Training

Time is tight, and your team can’t afford steep learning curves. The ideal system should require minimal training while ensuring protocol adherence. With CURIS’ smart automation and touch-of-a-button activation, even new users can quickly run a validated cycle—reducing human error and supporting cGMP protocols.

-

Compact Design and Unrestricted Storage

The best portable solution is one that’s effortless to store and always ready. Large equipment and high-concentration chemicals require extra space and must often be stored separately from operational rooms, while the CURIS 3’s compact footprint and non-hazmat (less than 8% hydrogen peroxide) solution minimize storage needs and can be kept wherever convenient.

-

Validated Efficacy + >6-Log Sporicidal Kill

It’s not disinfected unless it’s verified. CURIS' Hybrid Hydrogen Peroxide™ (HHP™) technology delivers consistent, validated biodecontamination with more than 6-log sporicidal efficacy—even in hard-to-reach areas like isolator gloves, underdeck spaces, and behind complex machinery. Ask for studies and industry references to see which equipment truly meets your needs.

It’s not disinfected unless it’s verified. CURIS' Hybrid Hydrogen Peroxide™ (HHP™) technology delivers consistent, validated biodecontamination with more than 6-log sporicidal efficacy—even in hard-to-reach areas like isolator gloves, underdeck spaces, and behind complex machinery. Ask for studies and industry references to see which equipment truly meets your needs.

-

Material Compatibility and Safety for Staff

Risk management teams often hesitate to approve harsh decontaminants that degrade equipment or endanger staff. CURIS’ lower concentration HHP™ solution is not only safer for materials like plastics, electronics, and HEPA filters, but it also offers faster return-to-service, reducing downtime and occupational risk.

Unlike high-concentration vapor systems, which operate at 400-1500 PPM, CURIS treatment cycles are effective at ≤135 PPM, greatly reducing risks associated with staff exposure to high concentrations of hydrogen peroxide.

-

Data Reporting and Regulatory Readiness

Every CURIS cycle is tracked and recorded. That means full documentation—date, duration, operator ID, and treatment outcome. Need to demonstrate due diligence during an audit? You’ll have automated proof at your fingertips, helping your QA team avoid regulatory headaches like Form 483 observations.

-

Multi-Use Flexibility with Nozzles or Hand Spray

Not every surface is a cleanroom. Some facilities need precision spraying in tight areas or under racks. The CURIS 3 can be implemented in many ways—whole room biodecontamination (main generator), targeted surface treatments (optional hand sprayer), and semi-fixed applications (optional integration with wall-mounted nozzles)—all in one system.

Not every surface is a cleanroom. Some facilities need precision spraying in tight areas or under racks. The CURIS 3 can be implemented in many ways—whole room biodecontamination (main generator), targeted surface treatments (optional hand sprayer), and semi-fixed applications (optional integration with wall-mounted nozzles)—all in one system.

Final Thoughts: Don’t Let Logistics Block Your Biodecontamination Strategy

Your biodecontamination system should work for you—not against your budget, your staff, or your compliance goals. The CURIS 3 offers plug-and-play simplicity, industry-proven efficacy, and the kind of real-world flexibility that turns “we should disinfect more” into “we already did.”

Ready to bring smarter, safer disinfection to your facility?