AI-Ready Disinfection Protocols | CURIS® Pharma 4.0™ Compliance

Biodecontamination Meets Digital Pharma: Creating AI-Ready Disinfection Protocols

Biodecontamination Meets Digital Pharma: Creating AI-Ready Disinfection Protocols

The pharmaceutical industry is undergoing a digital transformation, driven by Pharma 4.0™ principles. This framework emphasizes connected, intelligent, and adaptive manufacturing systems that integrate data across the entire product lifecycle . Artificial intelligence (AI), machine learning, and predictive analytics now play critical roles in optimizing quality control, equipment performance, and contamination prevention.

Yet AI is only as powerful as the data it receives. In environmental cleaning and biodecontamination—especially in aseptic processing—incomplete, inconsistent, or fragmented data won't suffice. Without structured, high-quality biodecontamination records, AI cannot deliver the predictive insights needed to protect patient safety and ensure regulatory compliance.

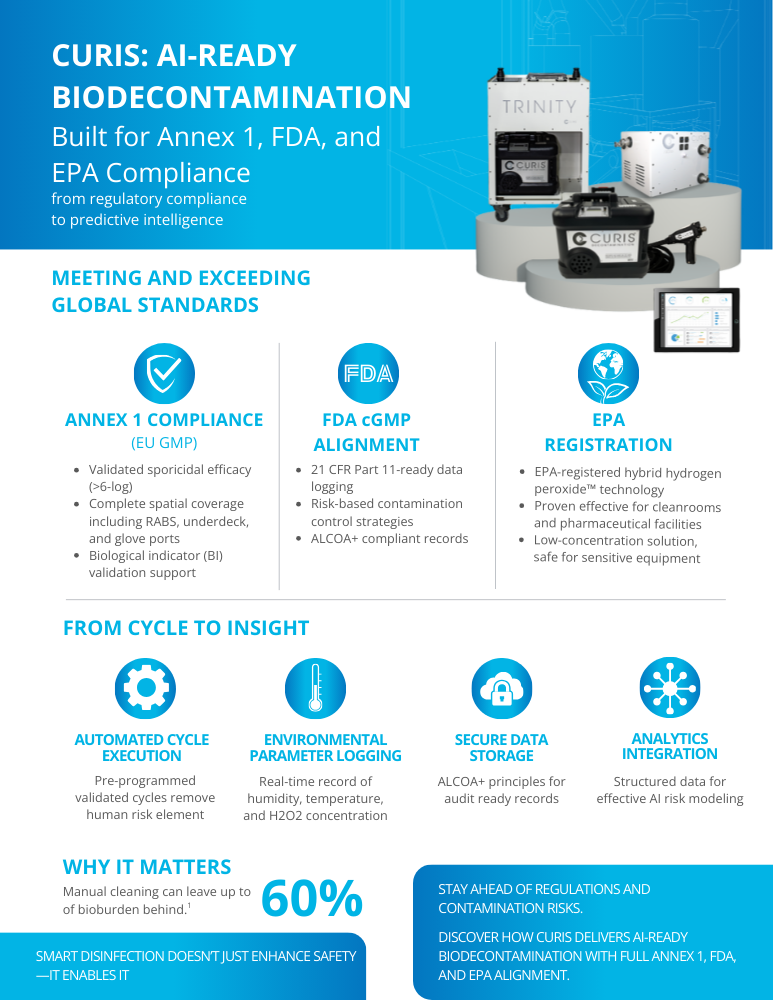

This is where CURIS System stands apart. Our intelligent, networked biodecontamination platforms go beyond disinfection—they capture, structure, and deliver AI-ready data aligned with the digital maturity expectations of Pharma 4.0™.

Turning Biodecontamination into a Digital Asset

CURIS® systems transform each disinfection event into a verifiable, regulatory-compliant dataset.

Each deployment of our patented Hybrid Hydrogen Peroxide™ (HHP™) technology can automatically record:

- Environmental conditions (humidity, temperature, hydrogen peroxide concentration)

- Cycle parameters (injection events, Pulse™ active dwell time, treatment duration)

- Operational anomalies (emergency stops, interruptions)

- Operator details for full traceability

All records are securely stored in an immutable, audit-ready format, compliant with FDA 21 CFR Part 11, supportive of ALCOA+ data integrity principles, and underpinned by EPA-registered disinfection chemistry. This foundation not only strengthens compliance but also builds the digital backbone required for Pharma 4.0™ data-driven operations .

From Reactive to Predictive: AI-Ready Biodecontamination

Traditional contamination control has relied heavily on manual spray-and-wipe disinfection, a process vulnerable to human error. Even with SOPs in place, variability in technique, surface coverage, and dwell time can leave behind contamination. In fact, many studies have shown manual cleaning can leave up to 60% of bioburden on surfaces.¹

Traditional contamination control has relied heavily on manual spray-and-wipe disinfection, a process vulnerable to human error. Even with SOPs in place, variability in technique, surface coverage, and dwell time can leave behind contamination. In fact, many studies have shown manual cleaning can leave up to 60% of bioburden on surfaces.¹

Paired with static cleaning schedules and anecdotal assessments, these reactive methods create blind spots that threaten compliance with EU GMP Annex 1 and FDA cGMP requirements.

CURIS replaces guesswork with validated, automated, and data-rich biodecontamination cycles, enabling predictive strategies:

- Analyze historical cycle data to uncover contamination risk trends by location, time of year, or process type

- Guide preventive maintenance based on environmental stressors and actual usage data

- Empower AI models to forecast deviations before they impact production

For example, aggregated CURIS data may reveal contamination spikes during specific times of year, such as product changeovers, maintenance shutdowns, or high-volume manufacturing runs. With this insight, facilities can proactively adjust disinfection schedules, deploy targeted interventions, and allocate resources more efficiently—preventing issues rather than reacting to them.

Built for ALCOA+, Annex 1, and FDA Compliance

To be AI-ready, biodecontamination data must adhere to ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, Available). CURIS ensures compliance by aligning with:

- FDA cGMP requirements for validated cleaning and environmental monitoring

- Annex 1 mandates for risk-based contamination control strategies, spatial coverage, and BI validation

- EPA registration for safe and approved use in pharmaceutical and cleanroom environments

By digitizing disinfection records, CURIS reduces the risk of FDA 483 observations or warning letters related to incomplete documentation or inadequate coverage.

Aligning with Pharma 4.0™

The ISPE Pharma 4.0™ framework emphasizes digital maturity, holistic quality, and data integrity as enablers of smart manufacturing . CURIS directly supports this vision by:

- Delivering validated, reproducible cycles across portable and integrated systems

- Providing optional automated logging tools (e.g., EnviroPod™) to strengthen deviation investigations

- Enabling seamless integration into BAS, supporting facility-wide digital quality systems

In short, CURIS doesn’t just disinfect—it generates structured, AI-ready data that makes facilities inspection-ready, audit-resilient, and digitally mature.

Why It Matters

In regulated industries, contamination represents both a compliance risk and a business threat. A single lapse can result in:

- FDA enforcement actions, including warning letters and production halts

- Costly recalls starting at $3 million or more

- Downtime and lost batches impacting patient supply

- Reputational damage that lingers beyond remediation

By embedding AI-ready, regulatory-compliant data into every disinfection cycle, CURIS enables:

- Consistent >6-log sporicidal efficacy, even in challenging environments

- Implementation of risk-based contamination control in line with Annex 1

- Deployment of predictive analytics to anticipate and prevent contamination

The question is no longer if digital biodecontamination data will be required, but whether your facility will have it when Pharma 4.0™ and AI-driven compliance systems demand it.

¹Shams A.M., Rose L.J., Edwards J.R., Cali S., Harris A.D., Jacob J.T., LaFae A., Pineles L.L., Thom K.A., McDonald L.C., et al. Assessment of the Overall and Multidrug-Resistant Organism Bioburden on Environmental Surfaces in Healthcare Facilities. Infect. Control. Hosp. Epidemiol. 2016;37:1426–1432. doi: 10.1017/ice.2016.198.