Customized Integrated Solutions

As part of our mission to provide high-level disinfection and decontamination technology for any space, CURIS works closely with individual facilities to design solutions to meet their specific needs, such as dedicated chamber systems, integrated room systems, and permanently mounted systems. These integrations are validated to provide >6-log repeatable sporicidal reduction of Geobacillus stearothermophilus.

Expert R&D for Innovative Disinfection

Our R&D team is comprised of innovators with a wide range of background, experience, and education. They include biodecontamination SMEs, engineers, fluid dynamics experts, mechanical designers, project managers, biologists, and more. This knowledge base helps address our customer's specific needs.

Flexible Integration Options Tailored to Your Facility

Our customized integration solutions offer adaptable options to meet your specific requirements, cycle times, workflow patterns, and budget considerations.

Partial Integration Systems: Adaptable Versatility

CURIS Modular Solutions provides a groundbreaking system that bridges the gap between integrated and portable decontamination. With permanently mounted nozzles, it seamlessly integrates into existing infrastructure. The partially integrated system allows you to connect a CURIS 3 HHP™ Portable Generator to the CURIS connection panel in an adjacent space. With ease, the quick connect application allows for use of the integrated nozzles.

CURIS Modular Solutions provides a groundbreaking system that bridges the gap between integrated and portable decontamination. With permanently mounted nozzles, it seamlessly integrates into existing infrastructure. The partially integrated system allows you to connect a CURIS 3 HHP™ Portable Generator to the CURIS connection panel in an adjacent space. With ease, the quick connect application allows for use of the integrated nozzles.

Our partial integration systems are engineered for maximum flexibility while maintaining the highest standards of biodecontamination efficacy. These modular solutions are particularly beneficial for facilities that:

- Experience regular reconfiguration of workspace layouts

- Need to deploy decontamination capabilities across multiple zones or departments

- Require dedicated decontamination spaces while maintaining portable options

- Operate with phased implementation budgets that necessitate incremental system adoption

Partial integration allows you to maintain operational agility without compromising decontamination effectiveness. These systems can be easily repositioned, reconfigured, or expanded as your facility's needs evolve.

How CURIS Partial Integration Works

When operating in integrated mode, the preset cycles ensure consistent, reliable decontamination. The permanent nozzles have an extremely low profile for unobtrusive, yet optimal coverage of hydrogen peroxide throughout your research environment. Additionally, CURIS partially and fully integrated systems eliminate shifting of where decontamination equipment is located, allowing for validatable biodecontamination while eliminating user error or variables.

It is very simple to run an integrated cycle.

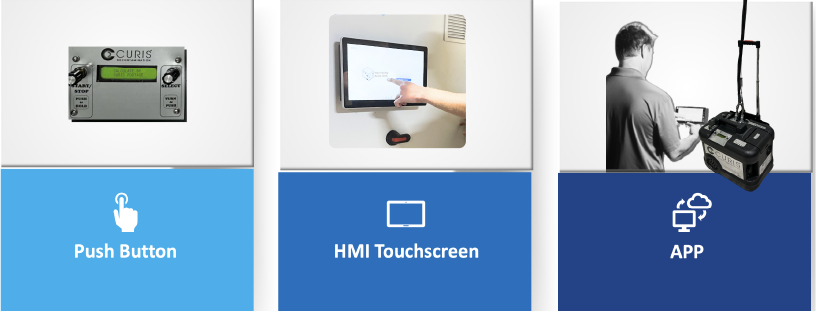

You can use the CURIS 3 HHP™ Generator as the source of the cycle by entering in the cycle parameters. This application is easy to run manually using the faceplate on the generator. Our most advanced option offers pre-programmed cycles (following cycle development) with audit tracking and reporting from a CURIS dedicated HMI Touchscreen. Or, you can run the cycle remotely via the CURIS Decon App using an iPad or Android Tablet, with reports accessible from the CURIS System website. These three different options allow for different levels of integration for successful bio-decontamination depending on your budget.

What markets use CURIS Integrated Systems?

- Biotech

- Biopharma Manufacturing

- High Containment Laboratories

- Public Health Laboratories

- Healthcare

Where can you use CURIS Integration?

- Decon chambers

- Cleanrooms

- Labs

- Animal Rooms

- Material Transfer

- Airlocks

- Pass Boxes

What can you decontaminate with it?

- Heat & Moisture-Sensitive...

- Lab Equipment

- Aseptic Filling Lines

- Vivarium Equipment

- Biosafety Cabinets

- Cell Sorters

- Animal Caging

- Incubators

The True Power of CURIS Partial Integration

Here's where it gets interesting… The CURIS 3 HHP™ Generator quickly detaches from the CURIS Connection Panel, transforming into a portable unit. This dual functionality offers unparalleled flexibility, catering to diverse decontamination needs. The less than 40-pound generator can easily be transported from one space to another, connect to a CURIS TRINITY™ for closed-loop bio-decontamination of BSCs, gnotobiotics, isolators, HEPA caissons, or more. It also allows for use with the CURIS Hand Sprayer for targeted biodecontamination or use of the nozzle directly on the generator for whole-space decontamination.

Full Integration Systems: Comprehensive Performance

Our comprehensive full integration solutions provide seamless incorporation of biodecontamination capabilities throughout your facility. These sophisticated systems deliver exceptional value when your operations demand:

- High-volume, continuous decontamination processing

- Rigorous documentation and validation protocols

- Operational efficiency with reduced personnel requirements

- Consistent, reproducible decontamination results

- Complete integration with existing BAS / BMS

Specialized Integration Options: Dual Delivery Systems

Our innovative dual delivery integration enables automatic switching between different-sized spaces from the same, low-concentration hydrogen peroxide system—delivering CURIS’ Rapid Vapor™ to smaller pass throughs and comprehensive HHP™ decontamination to larger spaces—and providing unprecedented flexibility for facilities with varying decon requirements. This adaptive technology ensures optimal hydrogen peroxide distribution regardless of spatial configuration.

Contact our integration specialists today to discover how CURIS customized integration solutions can enhance your facility's bio-decontamination capabilities while aligning with your operational requirements and budget parameters.

Fully Automated Decontamination Chambers

Need a completely separate, dedicated decon chamber? CURIS has many options for automated MAL and biodecontamination chambers. Visit our Decon Chamber webpage for more info.

Examples of Custom CURIS Systems

To date, here are a few of the customizations customers included that inspired the creation of some incredible high-level disinfection solutions:

To date, here are a few of the customizations customers included that inspired the creation of some incredible high-level disinfection solutions:

- CURIS Decontamination Chambers

- Pass through Integration

- Building Integration