Lab Disinfection & Sterilization With Hydrogen Peroxide

The integrity of scientific research, public health testing and surveillance, and pharmaceutical product development hinges on one fundamental principle: ensuring the highest levels of sterility. Effective disinfection and sterilization are vital to establishing a contamination-free environment in laboratories, a requirement that directly impacts the quality of outputs in these scientific spaces. Failures in sterility can lead to compromised experiments, skewed results, or even health risks.

Among the various methods available, hydrogen peroxide (H₂O₂) is a safer, more versatile solution. This widely used oxidizing agent is increasingly gaining recognition for its application in disinfection strategies for all types of laboratories and cleanrooms.

Explore the fundamentals of lab disinfection and sterilization with hydrogen peroxide so that you can exercise top-tier standards in your lab environment.

The Chemistry and Action of Hydrogen Peroxide

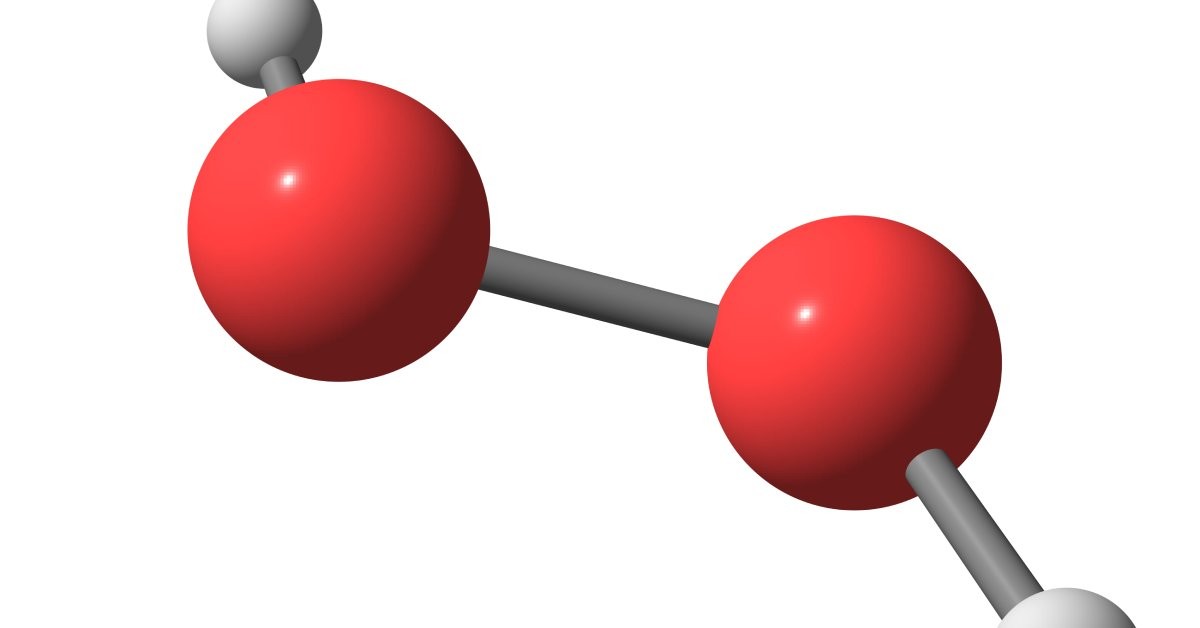

Hydrogen peroxide is a simple chemical compound comprised of two hydrogen and two oxygen atoms (H₂O₂). While structurally straightforward, its chemical properties make it one of the most effective sterilizing agents available today.

A powerful oxidizer, hydrogen peroxide releases oxygen upon decomposition, disrupting the cellular structures of microorganisms, including bacteria, viruses, fungi, and spores. This mechanism is particularly advantageous in a laboratory setting because it achieves high-level disinfection and sterilization without leaving behind harmful by-products.

Upon decomposition, hydrogen peroxide breaks down into water (H₂O) and oxygen (O₂), creating an eco-friendly solution that avoids the risks of toxic residues associated with alternative sterilizing agents like formaldehyde or ethylene oxide. Its biodegradability makes hydrogen peroxide an adaptable, sustainable component in sterilization protocols.

Applications of Hydrogen Peroxide in Lab Environments

Hydrogen peroxide’s versatility allows users to successfully apply it across various functions in laboratory settings, embodying a broad spectrum of disinfection and sterilization capabilities. From surfaces and equipment to the air itself, it serves as a multifunctional agent that addresses diverse contamination risks.

It’s important to note that the efficacy of hydrogen peroxide varies greatly, depending on the delivery method and system utilized. Therefore, for the purpose of this blog, we are referring to only EPA-registered solutions and their associated systems, which have been proven to reliable, achieve >6-log sporicidal reduction in all use cases.

For targeted surface disinfection, sprayed hydrogen peroxide can easily disinfect workstations, laboratory benches, and various items in high-traffic areas. For complete disinfection of all surfaces within a lab, including walls, ceilings, and floors, automated delivery systems excel at enveloping the whole lab with highly effective vaporized hydrogen peroxide. CURIS' patented HHP™ Technology (Hybrid-Hydrogen Peroxide Technology) is the latest advancement designed to mitigate high concentration issues, yet provide the needed pathogen kill.

Equipment sterilization also benefits from hydrogen peroxide. The vaporized form penetrates hard-to-reach crevices for high-level decontamination of many devices, including isolators, incubators, and sensitive instruments, such as particle counters. The CURIS TRINITY™ offers patented HHP™ Vapor Technology to quickly and easily decontamination closed-loop equipment.

Specific applications vary across laboratory types. High-containment facilities, such as public health or university research laboratories, rely on hydrogen peroxide to prevent potentially harmful pathogens from migrating to the outside world (contained). They disinfect and sterilize diagnostic equipment, transfer environments, and whole labs between projects.

Meanwhile, pharmaceutical facilities use hydrogen peroxide vapor to achieve the highest levels of sterility assurance, preventing contaminants from the outside world from tainting their research or products.

H2O2 Safety and Regulatory Compliance

Of course, proper handling with attention to safety guidelines and best practices is crucial to mitigating hazards through implementing hydrogen peroxide lab disinfection and sterilization. Though eco-friendly in its decomposition, high-concentration hydrogen peroxide solutions are highly reactive and corrosive, requiring careful storage and application. On the other hand, innovative low-concentration solutions such as CURIS System’s are below the HAZMAT level, making shipping and storage easier and reducing risks associated with exposure. In all cases, labs maintaining stock solutions must carefully store hydrogen peroxide away from direct sunlight and clearly label the containers to avoid accidental exposure.

Regulatory standards also play an indispensable role in guaranteeing the safe application of hydrogen peroxide. Compliance with internationally recognized frameworks such as Occupational Safety and Health Administration (OSHA) guidelines or the Environmental Protection Agency (EPA) ensures that the disinfectant is within permissible exposure limits (PEL).

Training personnel on proper handling and response protocols can significantly reduce risks, ensuring the seamless integration of hydrogen peroxide into laboratory ecosystems.

Why Choose Hydrogen Peroxide Over Other Disinfection and Sterilization Methods?

When weighed against conventional decontamination methods, hydrogen peroxide distinguishes itself with a set of competitive advantages. Traditional approaches such as alcohol-based disinfectants, chlorine dioxide, and UV light may be effective on various microorganisms but often fall short in comprehensive microbial elimination or safety concerns across varying environments.

Unlike alcohol, high-level sporicidal disinfectant systems using hydrogen peroxide effectively neutralize bacterial spores, offering broader-spectrum performance. Similarly, while chlorine dioxide is an effective sterilant, it can cause acute respiratory distress if a person is accidentally exposed to the gas. Accidental exposure to low-concentration hydrogen peroxide poses much less of a threat.

Treatment using low-concentration hydrogen peroxide also avoids the equipment degradation that some chemical agents cause, maintaining the longevity of lab gear. The broad spectrum of activity and compatibility with sensitive materials make low-concentration hydrogen peroxide the preferred choice for sustainability-conscious facilities striving for decontaminated, safe environments.

Benefits of Hydrogen Peroxide in Diverse Environments

Across the scientific community, numerous laboratories can reap the benefits of hydrogen peroxide disinfection and sterilization. For example, your university-based biosafety laboratory may implement vaporized hydrogen peroxide as part of its protocol for decontaminating high-containment research spaces. This switch can significantly lower cross contamination risks and reduce downtime between experiments, providing a safer, more productive environment for researchers.

Public health labs can embrace hydrogen peroxide’s unparalleled efficacy, too. A high-quality diagnostics center can replace its labor-intensive spray-and-wipe protocol with faster, more comprehensive hydrogen peroxide vapor generation. Staff and risk management may also appreciate the reduced risk of exposure to dangerous disinfectant chemicals.

Practical Tips for Seamless Implementation

Introducing hydrogen peroxide disinfection into existing lab protocols requires deliberate planning and adherence to operational guidelines. Start by conducting an audit of your lab’s needs, identifying areas where hydrogen peroxide will achieve tangible effects. This could be through targeted surface treatment, whole-lab disinfection, or equipment sterilization.

Invest in the appropriate delivery mechanisms for hydrogen peroxide, which range from manual application devices to automated or integrated systems, depending on the scale of your operations. For example, CURIS System offers decontamination devices that sync with multiple devices for treatment of large spaces or pair with systems specifically designed for closed-loop decontamination. CURIS technology is as scalable and versatile as it is reliable for contamination control.

Establish a routine maintenance plan to ensure the continued consistency and effectiveness of disinfection. Regularly revisit contamination control protocols to remain aligned with the latest advancements in safety and regulatory updates concerning hydrogen peroxide use.

Elevate Sterility Standards With Hydrogen Peroxide

Hydrogen peroxide offers research scientists, lab managers, and biosafety officers a superior solution to achieving safer, thorough, eco-conscious disinfection. With its versatile applications, environmentally friendly profile, and unparalleled sterilization efficacy, it embodies the latest in laboratory hygiene practices.

For laboratories striving to elevate their sterility standards, hydrogen peroxide presents not just a preventive measure but a performance-enhancing asset capable of simplifying complexities in sterility management. Integrate this versatile compound into your lab’s disinfection framework to unlock a safer, more efficient environment.