Beyond Legacy H2O2 Methods: The Evolution of Hybrid Hydrogen Peroxide™ Technology

A recent article in Bioprocess Online comparing vaporized and aerosolized hydrogen peroxide bio-decontamination methods has sparked important discussions in the bio-decontamination technology space. The article raises valid points about the limitations of legacy low-concentration aerosolized systems and the efficacy advantages of vaporized hydrogen peroxide in certain applications. However, these comparisons highlight the need to discuss emerging technologies that have transcended the traditional dichotomy between vapor and aerosol systems and advanced aseptic bio-decontamination, breaking through old barriers.

Understanding the Legacy Methods' Limitations

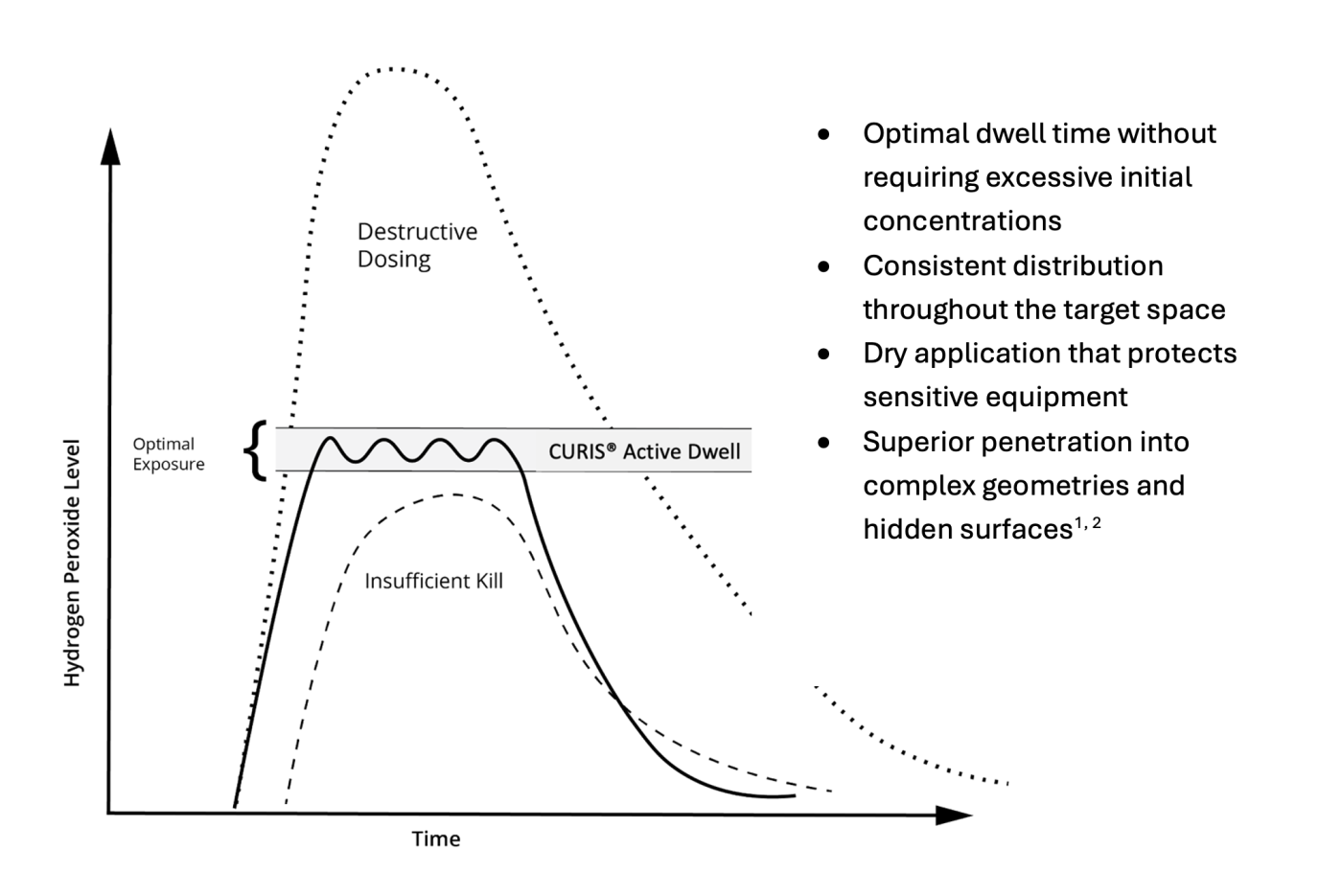

The article correctly identifies several key challenges with conventional approaches. Legacy systems of vaporized hydrogen peroxide require heat and high concentrations, while standard aerosolized systems may struggle with maintaining optimal exposure times and achieving consistent coverage. These observations align with our industry's long-standing understanding of these technologies' constraints.

Introducing a New Paradigm: Hybrid Hydrogen Peroxide™ Technology

What the article's comparison doesn't address is the emergence of next-generation technologies that bridge the gap between these legacy methods. CURIS's Hybrid Hydrogen Peroxide (HHP™) technology represents a fundamental advancement that delivers the best aspects of both approaches while eliminating their primary drawbacks.

The Power of Pulse™ Technology

At the heart of HHP™ technology lies our patented pulse™ technology, which revolutionizes how hydrogen peroxide is delivered throughout a space. Unlike legacy systems that require either heated vaporization or continuous aerosol generation, pulse™ technology ensures:

The No-Heat Delivery Advantage

One particularly noteworthy advantage of HHP™ technology is its ability to maintain efficacy without heating the hydrogen peroxide. This characteristic makes it:

- Faster to aerate, with minimal outgassing compared to legacy vapor systems3,4

- Less sensitive to environmental conditions that can impact legacy vapor systems using heated hydrogen peroxide, where microclimates are frequently observed2

- Ideal for decontaminating heat-sensitive equipment and materials2,4

Efficacy Without Compromise

While legacy methods often require trading off between effectiveness and equipment safety, HHP™ technology achieves superior efficacy while maintaining conditions kinder to surfaces and electronics.

The pulse™ delivery system ensures >6-log efficacy…

|

|

|

|

|

|

At much lower operating concentrations (ppm), compared to legacy vapor using high concentration chemicals5,6,7,8,9,10,11 |

In both large and small enclosures

|

Against a wide variety of organisms—bacterial spores, viruses, fungi, and bacteria

|

Through HEPA filters for comprehensive bio-decontamination

|

Looking Forward

As industry needs continue to evolve, it's crucial to move beyond the traditional vapor versus aerosol debate and embrace innovative solutions that address the limitations of both approaches. HHP™ technology represents not just an alternative to existing methods, but a fundamental advancement in bio-decontamination technology. By offering superior efficacy, environmental stability, and equipment protection in a single, innovative solution, HHP™ technology will play an increasingly important role in meeting these demands.

- Ghidoni, D., Grinstead, F., Held, K., Mullen, R., & Thibeault, R. (2018, March). Effectiveness of Aerosolized Hydrogen Peroxide in Simultaneous Decontamination of a Laboratory and a Biological Safety Cabinet. CURIS System.

- Material Compatibility with Hybrid Hydrogen Peroxide on Critical Laboratory Equipment and Sensors after 125 Cycles of Exposure. (2023). CURIS System.

- Ng, S., Massoth, B., Mowery, J. D., & VonEsch, M. (2024, April 17). Reimagining Decontamination: Low-concentration Hydrogen Peroxide Protocols. Interphex, New York, NY.

- Grinstead, F., Hislop, M., & Hoover, R. (2023). Material Compatibility and Sorption of High Containment Wall and Ceiling Materials when exposed to 7% and 35% Hydrogen Peroxide Decontamination. CURIS System.

- Khandelwal, A., Lapolla, B., Bair, T., Grinstead, F., Hislop, M., Greene, C., & Bigham, M. T. (2022). Enhanced disinfection with hybrid hydrogen peroxide fogging in a critical care setting. BMC Infectious Diseases, 22(1), 758. https://doi.org/10.1186/s12879-022-07704-9

- Henneman, J. R., McQuade, E. A., Sullivan, R. R., Downard, J., Thackrah, A., & Hislop, M. (2022). Analysis of Range and Use of a Hybrid Hydrogen Peroxide System for Biosafety Level 3 and Animal Biosafety Level 3 Agriculture Laboratory Decontamination. Applied Biosafety, 27(1), 7–14. https://doi.org/10.1089/apb.2021.0012

- Derr, T., & et.al. (2022). Aerosolized Hydrogen Peroxide Decontamination of N95 Respirators, with Fit-Testing and Viral Inactivation, Demonstrates Feasibility for Reuse during the COVID-19 Pandemic. M Sphere, 7(5). https://journals.asm.org/doi/pdf/10.1128/msphere.00303-22

- Cartwright, E., Grinstead, F., Mullen, R., & Watkins, L. (2021, October). A Multi-Facility Examination of Novel Technology for Gnotobiotic Decontamination: Efficacy within Semi-Rigid and Soft-Sided Isolators. CURIS System.

- Cutshall, A., & Grinstead, S. (2022, January). Analysis of Use of Hybrid Hydrogen PeroxideTM Technology for Complete Biodecontamination of Biological Safety Cabinets. CURIS System.

- Hybrid Hydrogen Peroxide for Viral Disinfection | IntechOpen. (n.d.). Retrieved December 8, 2024, from https://www.intechopen.com/chapters/79247

- Nims, R., & Ijaz, M. (2022). Disinfection of Viruses. Intech Open. https://www.intechopen.com/books/11006