Transfer Environment Bio-decontamination: Automated vs. Modular Solutions in Modern Life Sciences

In the complex world of life sciences and pharmaceutical manufacturing, choosing the right bio-decontamination system for transfer environments can significantly impact a facility's efficiency, compliance, and bottom line. As technology advances and regulatory requirements evolve, facility managers must carefully evaluate whether modular or fully integrated systems best serve their needs.

The Changing Landscape

The industry has moved far beyond the traditional pass-through. As discussed in our previous blog about material transfer spaces, legacy decontamination methods like spray and wipe isopropyl alcohol and autoclaves were once the standard but have significant limitations for modern facilities. Today's facilities face many challenges: stricter regulatory oversight, demands for increased throughput, growing sustainability concerns, and the need to protect sensitive materials that traditional sterilization methods could damage. Modern solutions must address these challenges while maintaining the highest standards of contamination control.

Critical Evaluation Points

Successful implementation begins with a thorough assessment of facility requirements. Key considerations include:

Transfer Frequency: Research facilities processing occasional items have vastly different needs than pharmaceutical manufacturing plants with continuous material flow. While modular systems provide flexibility for intermittent use, high-throughput environments typically benefit from automated, integrated solutions that minimize manual intervention and reduce human error risks.

Material Compatibility: The nature of transferred materials significantly influences system selection. Temperature-sensitive biologics, electronic equipment, and moisture-sensitive components require gentler approaches than standard laboratory equipment. Modern hydrogen peroxide vapor systems, particularly those using lower concentrations (7%) with optimized delivery methods, can effectively decontaminate sensitive materials without causing damage.

Understanding Integration Options:

Partial Integration (Modular Systems)

These systems prove advantageous when facilities:

- Undergo frequent layout changes

- Require mobility between different areas

- Face budget constraints necessitating gradual implementation

- Experience variable transfer volumes

Full Integration Benefits

Complete integration becomes valuable when facilities require:

- Consistent, high-volume throughput

- Stringent documentation and validation

- Reduced labor costs

- Exceptional process reproducibility

The Cost Equation

Beyond initial equipment investments, facilities must consider several long-term factors:

Labor Requirements: Modular systems typically require more hands-on operation. In regions with high labor costs, the initial savings can quickly evaporate.

Validation Burden: Fully integrated systems typically provide more comprehensive data collection and documentation capabilities—a crucial consideration when facing regulatory audits. The documentation process can become particularly challenging when facilities must manually compile records from multiple standalone units. Modern systems, like CURIS, help facilities overcome this validation challenge by providing automated, detailed reports for every treatment cycle, accessible via cloud storage, HMI interface, or printable—a feature available even with their portable modular options.

Operational Efficiency: The ability to integrate with building management systems, door interlocks, and environmental monitoring can substantially reduce cycle times and minimize costly errors. Advanced automation technologies, such as CURIS' mobile application with pre-programmed cycles for each space, streamline operations while safeguarding against human error in the decontamination process.

Future Trends

The bio-decontamination industry continues to evolve toward more intelligent, connected systems: Key features to consider include:

- Real-time monitoring capabilities

- Enhanced data integrity features

- Programmable operation options

- Sustainable operational features

- Broad material compatibility

Strategic Decision-Making

Facilities must look beyond current needs when selecting a system. Future growth projections, changing regulatory landscapes, and long-term operational costs all play crucial roles in the decision-making process. Some facilities find success starting with modular systems that offer expansion or upgrade paths to full integration, providing flexibility as needs evolve.

The Optimal Solution

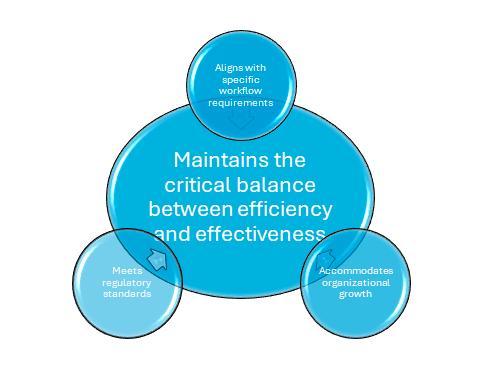

Facilities should carefully evaluate their unique circumstances rather than automatically choosing the most advanced or most basic option.

The Role of Professional Consultation

Given the complexity of these decisions, many facilities benefit from consulting with industry experts who can provide insights into system selection based on specific facility requirements, regulatory demands, and operational goals. These professionals can help evaluate current needs while considering future expansion possibilities and technological advancements.

Schedule a Consultation Now

Looking Ahead

As transfer environment bio-decontamination continues to evolve, facilities must stay informed about emerging technologies and changing industry standards. The most successful implementations often result from careful planning, thorough evaluation of facility needs, and consideration of long-term operational impacts.