What is Hybrid Hydrogen Peroxide™ (HHP™) Technology and how does CURIS System use it for decontamination?

Many biodecontamination systems rely on harsh chemicals such as formaldehyde, bleach, chlorine dioxide, or high-concentration hydrogen peroxide. While effective, these substances can:

- Harm staff or cause respiratory irritation, hospitalization, or even death

- Corrode sensitive equipment

- Leave sticky or toxic residues that promote microbial growth

The CURIS System’s Hybrid Hydrogen Peroxide™ (HHP™) Technology provides a safer, smarter alternative.

Using a 7% EPA-registered hydrogen peroxide formula, HHP™ combines unheated vapor and micro aerosols that remain suspended in the air for optimal contact time—ensuring uniform, dry biodecontamination.

Pulse™ Technology Advantage: CURIS’ patented Pulse™ system replenishes vapor levels throughout the process, maintaining peak efficacy while conserving solution. Devices auto-calculate the required dosage—no manual calibration needed.

Result: A dry, residue-free, and highly effective whole-room biodecontamination.

Where can the CURIS System be used for disinfection and decontamination?

The CURIS System is built for versatility, portability, and power. Despite its compact design, this device effectively disinfects and decontaminates sealed environments across a wide range of industries and facility types.

Common CURIS System applications include:

- Laboratories, cleanrooms, and research facilities

- Pharmaceutical and manufacturing environments

- Hospitals, clinics, and surgical suites

- Ambulances, emergency vehicles, and public transit

- Hotels, offices, and educational institutions

Because each facility has unique requirements, CURIS offers tailored solutions for different needs.

👉 Explore our product range: View CURIS Systems →

Is the CURIS System safe to use around electronics, fabrics, and sensitive equipment?

Yes. CURIS’ HHP™ vapor application is classified as a dry process, making it safe for use around electronics, fabrics, and delicate instruments when used as directed.

Extensive compatibility testing confirms that CURIS causes no corrosion, moisture buildup, or residue on sensitive materials—making it ideal for laboratories, cleanrooms, vivariums, and hospitals.

For in-depth testing results, please review our Material Compatibility White Papers →

- While bleach and quaternary ammonium disinfectants are widely available, they often create challenges in real-world applications:

- Require manual wiping or rinsing steps

- Can corrode metal and damage plastics

- Leave behind toxic residues and strong odors

- Risk operator exposure to harsh chemicals

- Potentially contribute to pathogen resistance

The CURIS System eliminates these concerns with a touchless, automated delivery of a non-corrosive, residue-free 7% hydrogen peroxide vapor. It provides a faster, safer, and more consistent way to eliminate pathogens across entire rooms and surfaces.

How much CURoxide™ solution does the CURIS System need to disinfect a room?

The required solution depends on the room’s size, contents, and target pathogens.

However, thanks to the patented Pulse™ HHP™ Technology, CURIS requires up to 30% less hydrogen peroxide solution compared to traditional vapor systems—without compromising performance.

Devices auto-calculate dosage to ensure optimal efficacy and resource efficiency.

Why is Pulse™ Technology critical for effective room disinfection with the CURIS System?

The CURIS Pulse™ Vapor Hydrogen Peroxide (VHP) technology is engineered to maintain consistent sporicidal disinfection efficacy across every surface.

By “pulsing” vaporized hydrogen peroxide throughout the cycle, the system maintains optimal concentration levels—achieving 6-log (99.9999%) reduction of bacterial spores and even coverage in complex spaces.

This method ensures:

- Maximum surface contact and dwell time

- Uniform distribution throughout the space

- Reduced chemical waste and faster treatment cycles

Does CURIS System offer biodecontamination services across the United States?

Yes! CURIS System provides nationwide biodecontamination services across all 50 U.S. states. Whether you're located in a major metro like Boston, Houston, or Los Angeles—or operating a cleanroom or fill-finish suite in smaller markets—we bring our expert team and patented Hybrid Hydrogen Peroxide™ (HHP™) technology directly to you.

We support pharmaceutical, biotech, life science, and high-containment facilities coast to coast with:

- Routine or emergency disinfection

- Equipment turnover

- Commissioning support

Regulatory compliance readiness

Learn more about our VHP biodecontamination services here.

What services does CURIS offer beyond its technology?

Beyond manufacturing cutting-edge systems, CURIS Biodecontamination Services provides on-site decontamination expertise across pharmaceutical, research, and biosafety facilities.

CURIS-Certified Technicians manage:

- Facility-wide decontamination projects

- Emergency response and contamination remediation

- Validation, documentation, and material compatibility assessments

In one recent deployment, CURIS treated 70 rooms in 11 hours—achieving 100% biological indicator success, showcasing the team’s unmatched efficiency and technical proficiency.

Can't we just use quaternary ammoniums and bleaches?

We are aware of the massive selection of products on the market, but there are many pitfalls with contamination control and infection prevention in often-complicated settings.

Some of the challenges with relying these chemicals, such as ammonium chlorides, bleaches, and chlorine dioxides may include:

- are most often not applied correctly

- often require a secondary step of rinsing

- will corrode surfaces

- can be toxic to the applicator

- often leave behind toxic residue and odors

- will leave behind sticky, ugly residues and require extra work to wipe them off

- can be deadly if mixed

- may contribute to resistant strains of pathogens

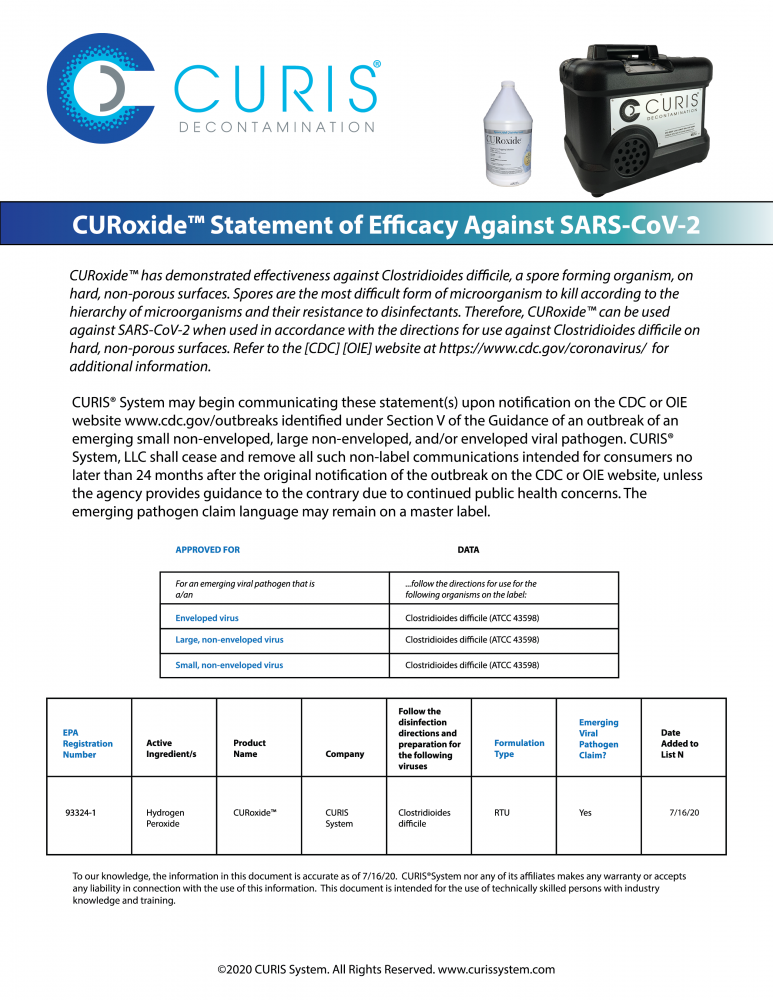

Is CURIS® on the EPA List N for use against SARS-CoV-2?

Yes, the CURIS System and its CURoxide™ solution are both EPA-registered and included on EPA List N for efficacy against SARS-CoV-2, the virus responsible for COVID-19.

This registration confirms that CURIS meets the EPA’s criteria for emerging viral pathogens and is approved for fogging and decontamination applications.

Can the CURIS System be used to disinfect spaces contaminated with COVID-19 and other viruses?

Absolutely. The CURIS System was specifically tested and approved for fogging disinfection against COVID-19 (SARS-CoV-2) and numerous other pathogens, including bacteria, viruses, and spores.

It's touchless HHP™ delivery ensures that every surface in a sealed space is evenly treated without the need for wiping or rinsing.

For verification, view our Statement of Efficacy → and CURoxide™ EPA registration.

How long does a CURIS System disinfection cycle take to treat a space or room?

Treatment duration varies based on the size, configuration, and air volume of each space. Smaller rooms require only minutes, while larger or complex facilities may take longer.

As a general benchmark, CURIS treatments take about the same time as UV light applications, but offer greater surface coverage and airborne decontamination.

What disinfectant solution does the CURIS System use and how does it work?

The CURIS System is paired exclusively with CURoxide™, a 7% hydrogen peroxide solution registered with the EPA.

When used together, CURIS and CURoxide™ are approved for a wide range of applications and appear on EPA Lists K & N, confirming their effectiveness against SARS-CoV-2 and other resilient pathogens.

This dual-registration ensures validated, compliant performance for whole-room disinfection.

Does CURIS offer portable or lightweight decontamination units for easier use?

Yes! The CURIS 3 was designed with portability and single-operator ease in mind. Weighing only 36 lbs, it offers full CURIS power in a compact, mobile design—perfect for frequent use and compliance-sensitive environments.

Is 7% hydrogen peroxide effective enough for biodecontamination in pharmaceutical environments?

Yes, Independent and joint validations have confirmed that CURIS® HHP™ technology using a 7% hydrogen peroxide solution can achieve complete (6-log) spore reduction in isolators, cleanrooms, and fill-finish lines—even in hard-to-reach areas. This efficacy is achieved through a unique closed-loop delivery system that continuously optimizes conditions (humidity, temperature, H2O2 levels) throughout the entire cycle—not just at the start—eliminating the need for a traditional "dwell" phase.

How does a 7% solution benefit material compatibility and equipment longevity?

Lower-concentration hydrogen peroxide greatly reduces the risk of oxidative degradation, which is common with 35–45% solutions. This means fewer issues like cracked seals, glove deterioration, HEPA filter damage, and corrosion of sensitive components See material compatibility. Facilities using CURIS® systems report longer equipment life, reduced preventative maintenance, and lower total cost of ownership—all without compromising disinfection efficacy.

What did CURIS showcase during its 2025 events?

Throughout 2025, CURIS presented at and exhibited during major life sciences and biosafety conferences, including:

- INTERPHEX 2025: Integrated HHP™ biodecontamination for isolators and transfer environments

- PharmaED Aseptic Processing Summit: Data on automated transfer-space decontamination

- ABSA International 2025: Advances in biosafety applications of HHP™ vapor

- ISPE Great Lakes Show: Risk-based contamination control strategies

- NCAB AALAS 2025: Low-concentration vapor applications for IVC racks in vivaria

- USDA ARS Symposium: Agricultural research collaboration on avian biosecurity

CURIS Webinar Series: Education on automating material transfer decontamination.

Each event reinforced CURIS’ leadership in innovative, validated contamination control technologies for regulated environments.

How does automated biodecontamination improve pharmaceutical manufacturing?

Automated biodecontamination systems like CURIS HHP™ remove the variability and downtime associated with manual cleaning methods. Through integrated cycle control, digital validation, and real-time monitoring, facilities can ensure every surface and enclosure receives uniform decontamination.

In pharmaceutical manufacturing, this directly supports Annex 1 compliance, GMP standards, and sterility assurance, reducing both human error and operational risk.

When should I schedule biodecontamination services for my facility?

Ideal times to bring in CURIS Biodecontamination Services include:

- Cleanroom commissioning or requalification

- Production shutdowns or facility maintenance windows

- Emergency disinfection after contamination events or failed EM

- Before or after audits to ensure compliance with Annex 1 or cGMP

Our mobile biodecontamination team travels to every U.S. state, delivering EPA-registered HHP™ vapor decontamination validated to >6-log kill. Every service includes on-site cycle documentation and proof of efficacy.

Read how our service saved one facility from costly downtime.

What makes CURIS System’s nationwide biodecontamination services different from others?

CURIS stands apart by offering:

- Low-concentration (7%) vapor that helps protect materials and staff while maintaining sporicidal efficacy

- Comprehensive cycle validation and documentation to meet FDA, cGMP, and Annex 1 compliance requirements

- Faster cycle times and aeration, minimizing production downtime

- Compatibility with sensitive equipment (e.g., isolators, lyophilizers, underdeck spaces)

- Expert deployment teams across the U.S., ready to meet your site’s specific needs

Explore the difference at our VHP Services page.

How is CURIS supporting biosafety and biocontainment laboratories?

CURIS technologies are widely used in BSL-2 to BSL-4 laboratories, animal research facilities, and high-containment agricultural environments.

Key biosafety benefits include:

- Validated sporicidal performance (≥6-log reduction)

- Compatibility with sensitive materials and electronics

- Reduced downtime due to rapid aeration cycles

- Comprehensive compliance documentation

CURIS’ field-proven systems have been adopted by academic, government, and private-sector laboratories seeking scalable disinfection solutions that meet evolving biosafety standards.

What industries and environments benefit most from CURIS technology?

CURIS solutions are trusted across multiple critical environments, including:

- Pharmaceutical and biotech manufacturing (aseptic fill-finish, isolators, transfer chambers)

- Academic and government research labs (BSL/ABSL containment)

- Vivarium and animal health facilities (IVC rack decontamination)

- Agricultural biosafety programs (avian and livestock research)

This cross-industry versatility ensures regulatory alignment and operational flexibility for every facility type.

Can CURIS support system validation and regulatory documentation?

Yes. CURIS provides GMP-compliant validation and digital reporting, documenting efficacy, cycle data, and environmental conditions. These reports are designed to meet FDA, EMA, and Annex 1 expectations.

Additionally, CURIS’ software supports audit-ready data management for both routine and emergency decontamination events.

How can facilities engage CURIS for consultation or demonstrations?

Pharmaceutical, biosafety, and research organizations can schedule a demo or consultation directly through CURIS’ contact portal at curissystem.com/contact.

The CURIS technical team offers virtual and on-site sessions, product demonstrations, and tailored validation guidance for GMP and BSL-compliant facilities.

How does CURIS technology contribute to sustainability in biodecontamination?

CURIS’ low-concentration HHP™ formula reduces chemical waste and power consumption compared to traditional systems. Automation further minimizes product loss and consumable overuse, aligning with ESG and sustainability goals in pharmaceutical and research operations.

By delivering faster aeration and less material wear, CURIS supports both environmental and operational sustainability.

What differentiates CURIS from other VPHP or vapor-based decontamination systems?

While many systems rely solely on vaporized hydrogen peroxide (VPHP), CURIS’ hybrid delivery blends micro-aerosol and vapor phases to achieve more even dispersion in complex geometries.

Key differentiators include:

- Validated automation: Auto-adjusts for multiple device synchronization

- Low-concentration chemistry: Minimizes material degradation

- Advanced reporting: Generates GMP-compliant digital documentation

- Scalability: Suitable for small biosafety cabinets or entire cleanrooms

These advantages make CURIS a preferred partner for pharma, biosafety, and life sciences organizations seeking long-term contamination control.